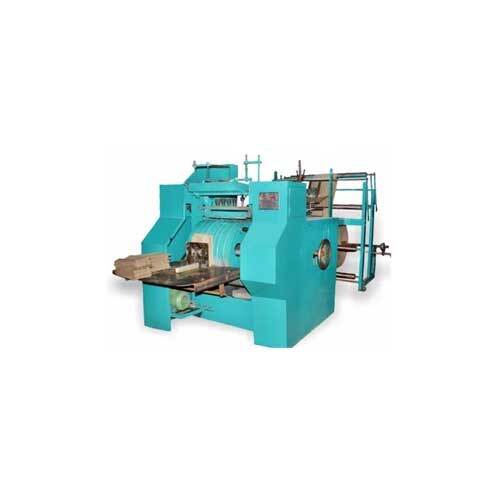

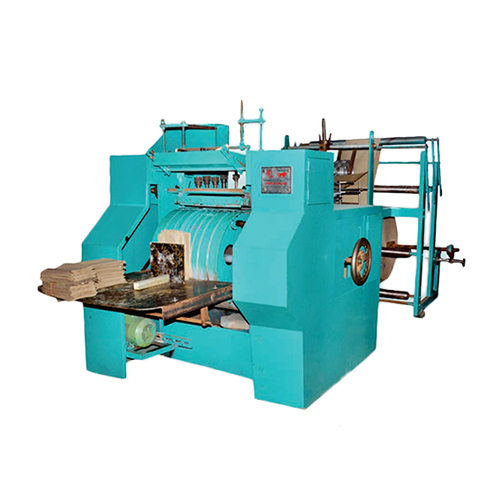

Fully Automatic Paper Bag Making Machine

उत्पाद विवरण:

- प्रॉडक्ट टाइप Fully Automatic Paper Bag Making Machine

- सामान्य उपयोग Manufacturing of paper bags for shopping, groceries, food packaging, and retail use

- दक्षता High production capacity, up to 150-250 bags per minute

- वजन (किग्रा) Approx. 3200 kg

- स्वचालित ग्रेड

- ड्राइव टाइप

- बैग का प्रकार

- अधिक देखने के लिए क्लिक करें

X

उत्पाद की विशेषताएं

- Manufacturing of paper bags for shopping, groceries, food packaging, and retail use

- Approx. 3200 kg

- 380V, 3 Phase, 50Hz

- High production capacity, up to 150-250 bags per minute

- Touch screen HMI, auto tension control, automatic counting, easy operation, quick size changeover

- Customization Available (Standard Light Grey or Blue)

- 12 kW

- Fully Automatic Paper Bag Making Machine

- 8700 x 2100 x 1900 mm

- 180-480 mm (adjustable)

- Available

- 70 mm - 320 mm

- 20 mm - 120 mm

- Automatic hot and cold glue system

- 1200 mm

- 60 - 220 bags/min (adjustable)

- ±1 mm

- 24/7 Support and Spare Part Supply

- ≤ 75 dB

- 0.6 MPa

- Inline printing unit, Die-cut window unit

- 900 mm

- 76 mm (3 inches)

- 35 gsm - 150 gsm

- PLC with HMI touch panel

उत्पाद वर्णन

Experience a sensational deal on the Fully Automatic Paper Bag Making Machinea true champion of efficiency and reliability. Engineered for exquisite precision, this machine accommodates bag widths from 70 mm to 320 mm and gusset sizes from 20 mm to 120 mm, guaranteeing a versatile range for any purchase requirement. Achieve cutting accuracy within 1 mm and enjoy adjustable production speeds up to 220 bags per minute. Featuring a PLC with HMI touch panel, servo motor drive, and automatic glue system, this machine ensures premium performance for every sale. Benefit from 24/7 after-sales support and installation service, making your investment truly outstanding.

Extraordinary Features and Plant Applications

The Fully Automatic Paper Bag Making Machine boasts exceptional features such as automatic tension control, photoelectric correction, and quick bag size changeover. Suitable for large-scale manufacturing plants in shopping, groceries, and retail, it uses an automatic method for bag production. With computerized controls and easy operation, manufacturers can efficiently process kraft, coated, or laminated paper. Optional units for inline printing and die-cut windows further emphasize its adaptability for diverse packaging needs.

Supplying Domestic and Export Markets

Our champion machine is widely supplied throughout India and handed over to numerous domestic manufacturers. The domestic market thrives on its efficiency, while main export markets include regions in Europe, the Middle East, and Africa. Sample policies are flexible, allowing samples to be delivered with prior arrangement. Whether for domestic mar or international partners, we ensure a seamless supply experience backed by dedicated support and prompt delivery.

Extraordinary Features and Plant Applications

The Fully Automatic Paper Bag Making Machine boasts exceptional features such as automatic tension control, photoelectric correction, and quick bag size changeover. Suitable for large-scale manufacturing plants in shopping, groceries, and retail, it uses an automatic method for bag production. With computerized controls and easy operation, manufacturers can efficiently process kraft, coated, or laminated paper. Optional units for inline printing and die-cut windows further emphasize its adaptability for diverse packaging needs.

Supplying Domestic and Export Markets

Our champion machine is widely supplied throughout India and handed over to numerous domestic manufacturers. The domestic market thrives on its efficiency, while main export markets include regions in Europe, the Middle East, and Africa. Sample policies are flexible, allowing samples to be delivered with prior arrangement. Whether for domestic mar or international partners, we ensure a seamless supply experience backed by dedicated support and prompt delivery.

FAQs of Fully Automatic Paper Bag Making Machine:

Q: How does the automatic paper bag making machine ensure cutting accuracy?

A: The machine incorporates advanced servo motor drive and computerized controls, including a photoelectric correction system, ensuring cutting accuracy within 1 mm for every bag produced.Q: What is the general process for producing paper bags with this machine?

A: Raw paper rolls are loaded onto the machine, unwound, cut to precise lengths, and shaped into bags using automated forming, gluing, and optional inline printing or die-cutting units. Finished bags are counted automatically and collected for packing.Q: Where can this machine be installed for optimal usage?

A: The machine is designed for installation in manufacturing plants specializing in shopping bags, grocery packaging, or other retail and food packaging. Installation service is available, ensuring smooth setup and operation.Q: What benefit does the PLC with HMI touch panel offer users?

A: The PLC-controlled HMI touch panel enables easy operation, rapid size changeover, and real-time process monitoring, enhancing overall efficiency and user convenience.Q: When can buyers expect after-sales support and spare parts supply?

A: Buyers enjoy 24/7 after-sales support and timely spare part supply upon the machines purchase, ensuring continuous operation and minimal downtime.Q: How flexible is the machine in handling different paper materials?

A: The machine can process kraft paper, coated paper, and laminated paper, covering a wide paper thickness range from 35 gsm to 150 gsm, making it suitable for multiple bag types and applications.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email